If you're renovating your kitchen or bathroom in Malaysia, you've probably come across two premium surface materials: sintered stone and porcelain slab. At first glance, they seem almost identical-both are large-format, engineered surfaces with stunning aesthetics and impressive durability. But are they really the same thing?

The short answer: No, they're not-though the terms are often used interchangeably in the Malaysian market, which can lead to confusion (and potentially costly mistakes).

In this guide, we'll break down the key differences between sintered stone and porcelain slab, explain the manufacturing processes, compare their performance characteristics, and help you decide which surface is right for your home.

What Is Sintered Stone?

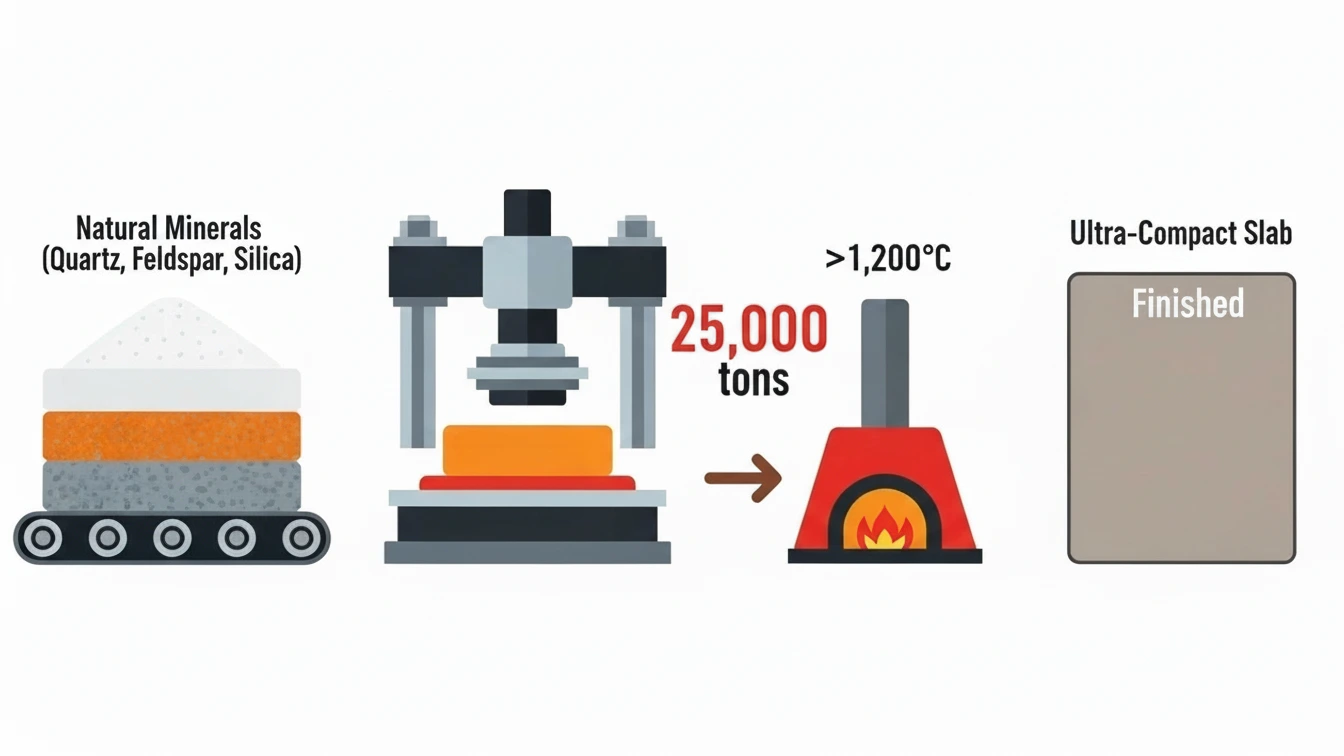

Sintered stone is a premium engineered surface made from a blend of natural minerals (such as quartz, feldspar, silica, and natural oxides) that are subjected to extreme heat (over 1,200°C) and pressure in a process that mimics the natural formation of metamorphic rock.

The term "sintered" refers to the process of compacting and forming a solid mass of material by heating it without melting it to the point of liquefaction. This creates an ultra-compact, non-porous surface with exceptional durability.

Key characteristics:

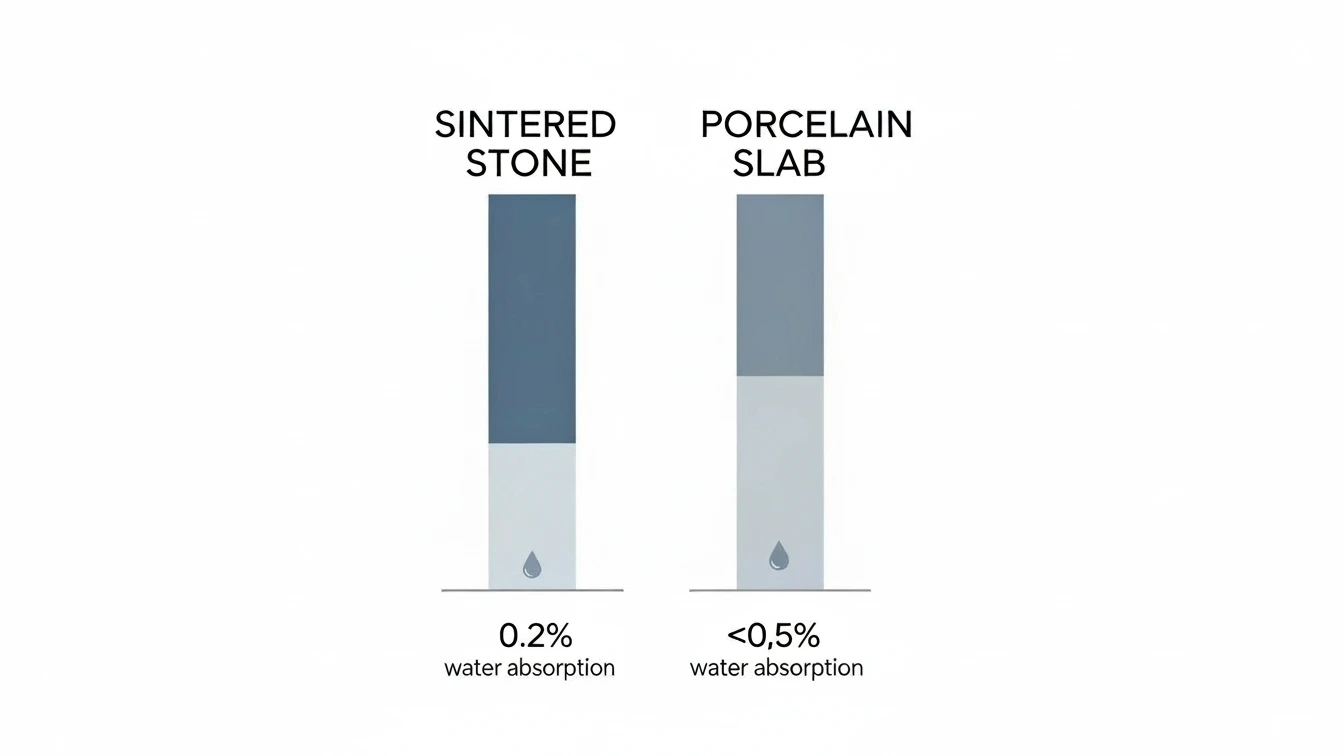

- Ultra-compact and non-porous (water absorption rate ≈ 0%)

- Highly resistant to heat, scratches, stains, UV, and chemicals

- Large-format slabs (commonly 3200mm × 1600mm or larger)

- Available in a wide range of thicknesses (4mm to 20mm)

- Premium pricing due to advanced manufacturing technology

Popular sintered stone brands in Malaysia include Dekton & Neolith

What Is Porcelain Slab?

Porcelain slab is a large-format version of traditional porcelain tile, made primarily from refined clay, kaolin, feldspar, and other minerals that are pressed and fired at high temperatures (typically 1,200°C to 1,400°C).

Modern porcelain slabs use advanced manufacturing techniques to create larger, thinner, and more consistent surfaces than traditional tiles. However, the core material composition and production process remain rooted in traditional ceramic manufacturing.

Key characteristics:

- Porcelain body with low water absorption (usually < 0.5%)

- Good heat and stain resistance

- Large-format slabs (similar sizes to sintered stone)

- Typically available in 6mm to 20mm thicknesses

- More affordable than sintered stone, but still a premium option

- Quality and performance vary significantly by manufacturer

Porcelain slab brands available in Malaysia include Moca Compact, Estella, Atlas Plan, and various Chinese and Italian manufacturers.

The Key Differences: Sintered Stone vs. Porcelain Slab

1. Manufacturing Process & Material Composition

Sintered Stone:

- Uses a blend of natural minerals (quartz, feldspar, silica, oxides)

- Extreme pressure (up to 400 bar) combined with heat (1,200°C+)

- To put this in perspective: Cosentino, the manufacturer of Dekton sintered stone, applies up to 25,000 tons of compression-equivalent to the weight of 2.5 Eiffel Towers pressing down on each slab

- Creates a metamorphic-like structure with zero porosity

- Full-body colouring (pattern runs through entire thickness)

Porcelain Slab:

- Primarily clay-based with ceramic minerals

- Pressed and fired at high heat (1,200-1,400°C)

- Lower pressure compared to sintered stone-typically 16,000 to 18,000 tons (according to some Chinese manufacturers)

- Some manufacturers intentionally reduce compression weight to balance performance with fabrication practicality

- May use full-body colouring or digital printing (varies by manufacturer)

The sintered stone process creates a denser, more compact material with superior performance characteristics, whilst porcelain slabs retain more traditional ceramic properties.

A Trade-off Worth Noting:

Whilst higher compression creates superior hardness and durability, it also makes the material more challenging to work with. Sintered stone at 25,000 tons compression can be difficult for fabricators to cut-often causing chipping and sparking during cutting. Porcelain slabs with lower compression (16,000-18,000 tons) strike a balance between performance and workability, which can translate to easier installation and potentially lower fabrication costs.

2. Density & Porosity

Sintered Stone:

- Ultra-compact with very low porosity (water absorption ≈ 0.02%)

- Extremely resistant to stains, bacteria, and moisture penetration

- Ideal for wet areas, outdoor kitchens, and humid Malaysian climates

Porcelain Slab:

- Low porosity (water absorption < 0.5%, per industry standards)

- Good stain resistance, but not quite as impervious as sintered stone

- Still suitable for kitchens and bathrooms, but performance depends on quality

For Malaysian homeowners, this difference matters: in our humid, tropical climate, a truly non-porous surface offers superior hygiene and longevity.

3. Heat Resistance

Sintered Stone:

- Can withstand extreme heat (up to 300°C or higher)

- You can place hot pots and pans directly on the surface without damage

- Highly UV-resistant, making it excellent for outdoor applications (e.g., outdoor kitchens, BBQ islands)

Porcelain Slab:

- Good heat resistance (typically up to 250°C)

- Generally safe for hot cookware, but extreme or prolonged heat may cause issues with lower-quality products

- UV-resistant, but performance varies by brand

If you're planning an outdoor kitchen or alfresco dining area in Malaysia, sintered stone's superior heat and UV resistance give it a clear edge.

4. Scratch Resistance

Sintered Stone:

- Extremely hard surface (Mohs hardness ≈ 7 or higher)

- Highly resistant to scratches from knives, utensils, and daily use

- Safe to cut directly on the surface (though we don't recommend it to preserve your knives!)

Porcelain Slab:

- Good scratch resistance (Mohs hardness ≈ 5-6)

- Can withstand normal kitchen use, but more susceptible to scratching than sintered stone

- Higher-quality porcelain slabs perform better

In a busy Malaysian kitchen where you're preparing roti canai, chopping vegetables, and moving woks around, the extra scratch resistance of sintered stone can be reassuring.

5. Price Point

Sintered Stone:

- Premium pricing: typically RM300-RM350+ per square foot (supply & install) depending on brand, thickness, and finish

- For example, Dekton sintered stone averages around RM317 per square foot

- Installation costs are higher due to the material's hardness and need for specialised cutting tools

- This is a significant investment, but reflects the advanced manufacturing technology and superior performance characteristics

Porcelain Slab:

- Price range varies dramatically: RM110-RM650+ per square foot (supply & install) depending on origin, brand, and quality

- Budget-friendly options: Malaysian brands like Moca Compact average around RM110 per square foot—offering excellent value for homeowners with tighter budgets

- Premium Italian porcelain: Brands like Atlas Plan range from RM318-RM654 per square foot, rivalling or exceeding sintered stone prices whilst offering Italian craftsmanship and design

- Installation costs are generally comparable to sintered stone for premium porcelain slabs

The key insight: not all porcelain slabs are budget options. Premium Italian porcelain can cost as much as or more than sintered stone, whilst Chinese-manufactured porcelain slabs offer a more accessible entry point for Malaysian homeowners seeking large-format surfaces on a budget.

6. Availability & Brand Reputation

Sintered Stone:

- Fewer brands and suppliers in Malaysia

- Dominated by established European brands (Dekton & Neolith)

- Higher quality control and consistency

- Better documentation and certifications

Porcelain Slab:

- Many brands and suppliers, from premium Italian to budget Chinese manufacturers

- Quality varies significantly-some are excellent, others are subpar

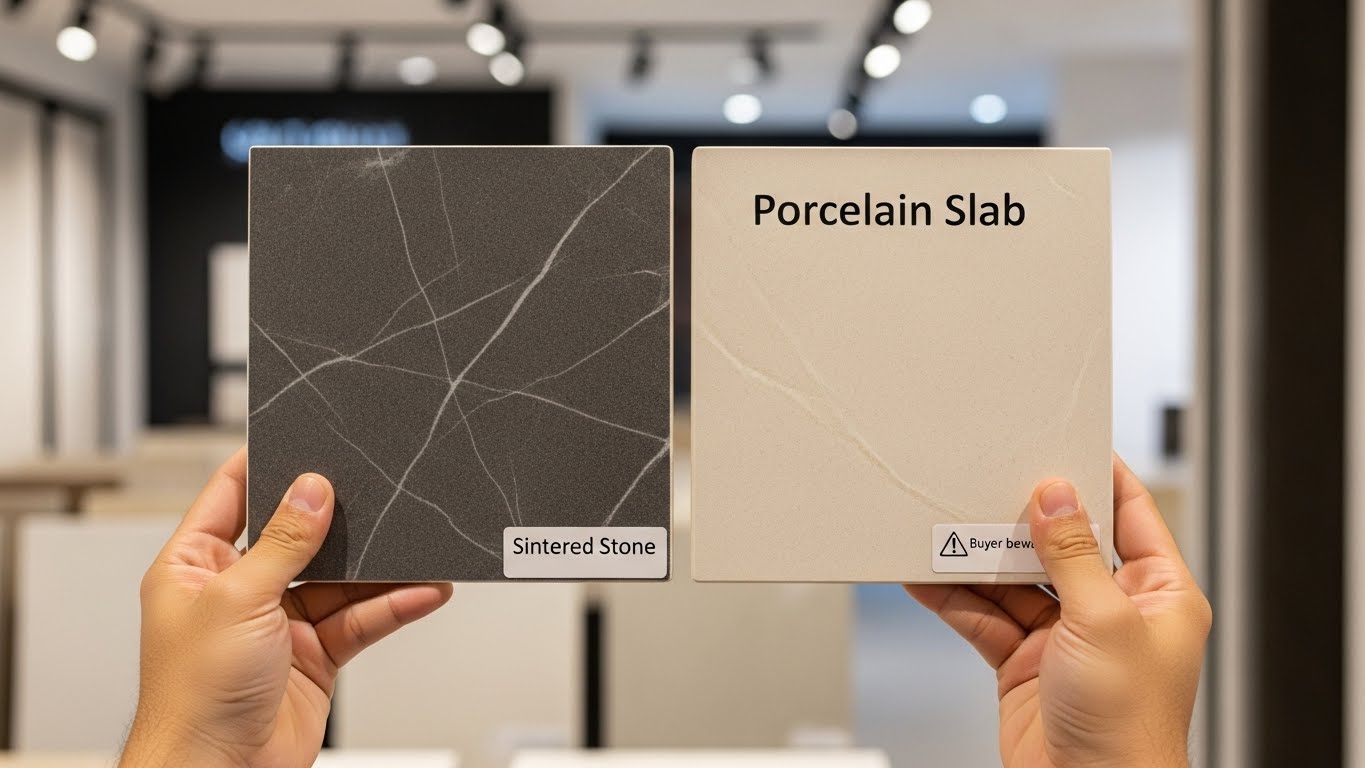

- Risk of mislabelling or misrepresentation (e.g., lower-grade porcelain sold as sintered stone)

Buyer beware: The Malaysian market has seen cases where porcelain slabs are marketed as "sintered stone" to command higher prices. Always verify the brand, ask for technical data sheets, and work with reputable suppliers.

For more detailed information on quality variations, read our guide on Not All Porcelain Slabs Are Suitable for Kitchen Countertops.

Which One Should You Choose?

Choose Sintered Stone if:

- You want the absolute best performance (heat, scratch, stain resistance)

- You're planning an outdoor kitchen, BBQ island, or alfresco dining area

- You prioritise ultra-low maintenance and hygiene (zero porosity)

- Budget is less of a constraint, and you want a premium, long-term investment

- You value established brand reputation and consistent quality

Choose Porcelain Slab if:

- You want excellent performance at a more accessible price point

- Your application is indoors (kitchen countertops, bathroom vanities, feature walls)

- You're willing to research and verify the manufacturer's credentials

- You want a wider range of design options and price tiers

- You're working with a tighter renovation budget

Are They Really Different?

Yes-sintered stone and porcelain slab are distinct products, even though they share similarities in appearance and application.

The confusion arises because:

- Both are large-format, engineered surfaces.

- Both are made from natural minerals and fired at high heat.

- Marketing language in Malaysia (and globally) sometimes conflates the two.

However, the manufacturing process, material density, and performance characteristics differ. Sintered stone undergoes a more extreme process (higher pressure, specific mineral blend) that results in a denser, more durable surface. Porcelain slab, whilst still a high-quality product, retains more traditional ceramic properties.

Why Is It Called "Porcelain Slab"?

The naming convention makes sense when you understand the manufacturing lineage: porcelain slabs use a process fundamentally similar to traditional porcelain tile production (clay-based materials, pressing, and firing) but scaled up to produce large-format slabs. Because the compression levels (16,000-18,000 tons) don't reach sintered stone density, the resulting product remains closer to porcelain in its material characteristics-hence "porcelain slab" rather than "sintered stone." It's essentially large-format porcelain, not a different material category altogether.

To understand the technical details behind sintered stone manufacturing, check out The Science Behind Sintered Stone.

Avoiding Material Misrepresentation

Here's how to protect yourself when shopping for premium surfaces in Malaysia:

- Ask for the brand name and technical data sheet - Legitimate manufacturers provide detailed specifications, including water absorption rates, hardness, and certifications.

- Verify with the brand's official distributor - Contact the brand directly to confirm your supplier is authorised.

- Request samples and inspect closely - Check for consistent full-body colouring, examine the edges, and feel the weight and density.

- Be wary of "too good to be true" pricing - If a supplier offers "sintered stone" at porcelain slab prices, question whether you're truly getting sintered stone.

- Work with reputable suppliers - Choose suppliers with a track record, showrooms, and transparent documentation.

Final Thoughts

Both sintered stone and porcelain slab are excellent premium surfaces for Malaysian homes, offering durability, beauty, and low maintenance. Your choice depends on your specific application, performance priorities, and budget.

If you want the ultimate in performance and are investing in a high-end kitchen or outdoor space, sintered stone is worth the premium. If you're seeking a beautiful, durable surface at a more accessible price for an indoor kitchen or bathroom, porcelain slab is an outstanding choice-provided you do your homework and choose a reputable brand.

At Sinno, we carry both sintered stone and porcelain slab options from trusted manufacturers. Visit our showroom in Klang Valley to see and feel the difference for yourself, and our team will help you choose the right surface for your renovation.

For more comprehensive comparisons, explore: